Hydrostatic testing

After the initial test, the results are stamped into the body of the scuba tank, along with the date (year and month) it passed. A common hydrostatic test is to pressurize the scuba tank to 5/3 of its working pressure and to measure the flexing of the tank walls. Five-thirds of a 3,000 psi working pressure means that the tank will be pressurized to 5,000 psi. This is done by replacing the valve with a special hydraulic testing connection and filling the scuba tank with water under pressure – NOT air!

Air would be too explosive if the tank were to let go during the test, as it sometimes will. Because water cannot be compressed, the tank cannot explode if it fails.

Testing is done inside an armored vessel. The tank is also under water, and they measure the amount that a water column rises as the tank is pressurized. This measures the amount of tank expansion. The water inside does not expand, but the aluminum or steel tank casing certainly does! They are looking for tanks that DO NOT expand as much under pressure, indicating that their walls have been work-hardened over the years. Like a piece of steel that is repeatedly flexed, the tank walls get hard to the point that they may suddenly fail with a snap. This is EXTREMELY rare outside the testing station. When it DOES happen, it’s almost always fatal to people standing close by.

You know it when they fail!

When a tank fails during hydro, it’s usually the valve threads that let go. It sounds like a loud “whump”. The other thing that sometimes happens, but not as often, is that the bottom of the tank bursts open. This is due to corrosion. If the tank fails to flex enough during the test, it can never be filled with air again, and no dive shop will do so. It will not be stamped with a current test stamp (one within the past five years) and is “out of hydro” as far as any dive shop is concerned. When a tank fails during hydro, it’s usually the valve threads that let go. It sounds like a loud “whump”. The other thing that sometimes happens, but not as often, is that the bottom of the tank bursts open. This is due to corrosion. If the tank fails to flex enough during the test, it can never be filled with air again, and no dive shop will do so. It will not be stamped with a current test stamp (one within the past five years) and is “out of hydro” as far as any dive shop is concerned.

The annual visual inspection is performed by our shop technicians. They let the air out of the tank and removes the valve to have a look inside. They’re looking for signs of corrosion and will refuse to put a visual inspection sticker on the tank if they find any. These stickers are paper or plastic and they stick to the tank. The annual visual inspection is performed by our shop technicians. They let the air out of the tank and removes the valve to have a look inside. They’re looking for signs of corrosion and will refuse to put a visual inspection sticker on the tank if they find any. These stickers are paper or plastic and they stick to the tank.

They open the valve a little to slowly let the air out. This prevents condensation from rapid cooling. It takes 12 hours or more for a tank to bleed down – especially since airgunners seldom let their tanks drop below 2,000 psi. Let us bleed your tank for you; we know what we doing! |

|

Controlled by the U.S. Department of Transportation

Pressure vessels are regulated by the DOT for the safety of transport vehicles, their passengers and the environments through which they pass. Every scuba tank model must pass an initial DOT certification, then EACH manufactured scuba tank must pass a test before it can be sold. This is 100 percent inspection that even racing tires are not subjected to! It is somewhat equivalent to space specifications, so this is an extremely well-controlled industry!

|

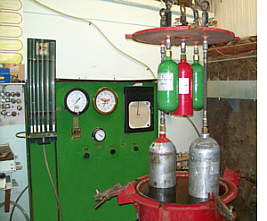

Hydrostatic Testing

Stored-pressure fire extinguishers must be hydrostatically tested

at certain time intervals by following procedures specified by

NEPA and DOT (Department of Transportation). A hydrostatic test

is a "pressure test". It is performed on an extinguisher cylinder to

check for structural weaknesses or flaws.

An external inspection

of the cylinder is also performed to check for excess pitting,

corrosion, oriphysidal-de (15E-Tnities. In addition, an internal

inspection is performed on the extinguisher before it is recharged

and returned to service.

Hydrostatic tests verify the performance of fluid pressure vessels. Using this test helps maintain

safety standards and durability of a vessel over time. Newl y manufactured pieces are initially qualified using the hydrostatic test. They are then continually re-qualified at regular intervals using the proof pressure test which is also called the modified hydrostatic test. y manufactured pieces are initially qualified using the hydrostatic test. They are then continually re-qualified at regular intervals using the proof pressure test which is also called the modified hydrostatic test.

Hydrostatic testing is also a way in which a gas pressure vessel, such as a gas cylinder or a boiler, is checked for leaks or flaws.

Testing is very important because such containers can explode if they fail when containing compressed gas.OSHA 1910.57(e)(4) states: “the employer shall assure that all stored pressure dry chemical fire extinguishers that require 12 year hydrostatic tests are emptied and subjected to applicable maintenance procedures…”

Periodic tests are mandated by NFPA and Department of Transportation (D.O.T.) requiring specialized test equipment to ensure the integrity of a cylinder at its listed operation pressure. Extinguishers are hydro-tested at intervals bases on NFPA 10 and high pressure cylinders are to be tested according to D.O.T. specs.

|

We can provide hydro-testing

on the following equipment:

- Hand Portable Fire Extinguishers

- Clean Agent Cylinders

- Fire Suppression Systems Tanks

- SCBA Tanks

- SCUBA Tanks

- Oxygen Cylinders

- High Pressure Cylinders

|